Corrosive Media Silicon Carbide Mechanical Seals

Mechanical seals for corrosive media, corrosion and wear is the main cause of friction in the form of paid material failure. This highly corrosive effect, directly or quickly cause changes in sealing performance, so to be selected according to the characteristics of the sealing material is sealed paid media. Corrosive media silicon carbide mechanical seals have good chemical stability, strong corrosion resistance, and therefore can be applied to a variety of corrosive acid and alkaline media.

Mechanical seal in the actual application process, the sealed fluid often contain corrosive media, such as waste water to be treated, the water in some waters, some of the chemical solution, these liquids contain corrosive media, corrosive media silicon carbide mechanical seals because of its excellent performance, it can be used as a sealing material of high PV value, strong corrosion, high temperature, dry friction conditions and containing solid particles, has good application prospects.

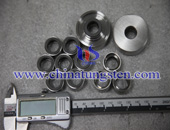

Corrosive media silicon carbide mechanical seals has good chemical stability, and therefore suitable for a variety of corrosive acid media. Corrosive media silicon carbide mechanical seals with good wear resistance, high temperature resistance, chemical resistance and other characteristics, has recently been widely applied to many fields. Currently, there are two common silicon carbide products, which are reaction-bonded silicon carbide and sintered silicon carbide. Reaction bonded silicon carbide ceramics with respect to the non-pressure solid-phase SiC impatience acid and alkali. The use of non-pressure solid phase sintering of silicon carbide, and its resistance to corrosion in acid and alkali is much better than the reaction bonded silicon carbide. Sintered silicon carbide and silicon carbide hot single phase structure, good corrosion resistance. The reaction-bonded silicon carbide due to the presence of free silicon, it is not for the strong oxidant media.