Silicon Carbide Seals Pressureless Sintered Process

Silicon carbide seals usually Sintering. SiC seal material in the preparation process, the most important part is sintered silicon carbide sintering pressure sintering method, reaction sintering, hot pressing, hot isostatic pressing and sintering, recrystallization sintered carbide for sealing silicon sintering using atmospheric sintering, reaction sintering and hot pressing sintering three methods. Three methods have their own characteristics, and therefore the performance of sintered silicon carbide seals are also differences. But overall, the sealing performance of silicon carbide material is relatively superior, can use as a sealing material.

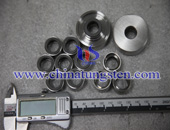

Sintered silicon carbide seals usual process of milling, mixing, spray granulation, molding, sintering and post-processing. Pressureless sintering is considered to be the most beneficial to the industrial production of silicon carbide sintering method, by pressureless sintering process can be prepared by complex shapes and large size silicon carbide components. Depending on the firing mechanism and sintering aids, non-sintered silicon carbide can be divided into solid and liquid phase sintering sintering.

Silicon carbide seals because of its resistance to abrasion, high temperature and corrosion-resistant properties, is widely used in various mechanical seal hard on hard occasions. Without sintered silicon carbide and other materials to be large compared to the advantages of independence thick, compared with the reaction sintering tungsten carbide sintered silicon carbide can be used normally at 1600 ℃, and in acid and alkali conditions, no pressure SiC was superior corrosion resistance of tungsten carbide, aluminum oxide and reaction bonded silicon carbide. This is because these characteristics, silicon carbide seals are widely used in all kinds of pumps, engines and automotive sealing member.