Silicon Carbide Mechanical Seal Ring Performance Requirements

Mechanical seal ring is the ring and stationary ring, collectively, are the most important elements of mechanical seals. Silicon carbide mechanical seal ring largely determines the mechanical seal performance and life, in order to ensure the mechanical seal sealing ring normal operation, from reducing wear, corrosion, and other considerations to prevent the bite, usually silicon carbide mechanical seal ring Performance requirements of the as follows:

1) the physical and mechanical properties. Require silicon carbide mechanical seal ring has an elastic modulus, high mechanical strength, low density, thermal conductivity, low coefficient of thermal expansion, thermal cracking and thermal shock resistance;

2) chemical properties. Require silicon carbide mechanical seal ring corrosion resistance, anti-swelling, aging; good corrosion resistance seal ring can resist corrosion and corrosion and wear of the fluid to extend the working life. Especially in the chemical industry with acid, alkali and other corrosive media, should be selected corrosion resistant materials;

3) tribological properties. Require silicon carbide mechanical seal ring self-lubricating, low friction coefficient, can withstand short-term dry friction, wear resistance, good compatibility. Seals must pay due to friction rotation, only their material wear good enough, but also consider the compatibility problems paying friction material pair. When two materials are composed of poor compatibility friction pay prone adhesive wear. Only good material compatibility group right, to get good self-lubricating properties and wear resistance;

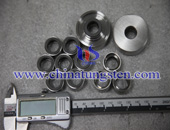

4) seal ring easy manufacturing. Silicon carbide mechanical seal ring should have good molding and processing properties, high precision seal face, the end face roughness of generally less than 0. 4 μm; flatness is generally less than 0. 9 μm.