High Temperature Silicon Carbide Mechanical Seals

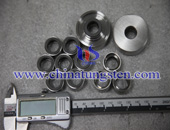

With the rapid development of modern science and technology in the petrochemical industry, chemical, fertilizer, nuclear, aerospace and machinery manufacturing, and mechanical seals put a higher demand. It is well known to improve the high temperature performance is to ensure that an important part of the life of mechanical seals and sealing performance. High temperature silicon carbide mechanical seals due to its high accuracy, wear resistance, high temperature resistance, chemical resistance, excellent performance, is often applied to the harsh conditions of the occasion.

High temperatures can lead to changes in the material properties of friction to pay, so that the seal face deformation, lower hardness, resulting in deterioration of the mechanical seal life. As the high temperature thermal deformation of the sealing material pay, high temperature strength and wear resistance are key issues when selecting a sealing material to pay consideration. High temperature silicon carbide mechanical seals having a high temperature strength, such as substantially the same as the normal temperature of the hot pressing of silicon carbide at 1 600 ℃ when the bending strength, so as to avoid high temperature creep phenomenon similar metal, and because carbonized Self-lubricating ceramic silicon, which rotates between the end surfaces and will not appear adhesive wear, so the high temperature silicon carbide mechanical seals for high temperature conditions of the mechanical seal.

High temperature silicon carbide mechanical seals has good high temperature mechanical properties and thermal properties, suitable for high temperature fluid seal material, and can be used for hot water, hot oil, hot fluids, under certain conditions without the use of a cooling unit.