Silicon Carbide Seal Material Wear Resistance

Under normal circumstances, the mechanical seal is undesirable friction, but in some cases they can not be completely avoided, for example, the mechanical seal faces due to the fluid force increases, the gap is reduced, due to the sealing surface will seal pay asperity contact temperature Start or other reasons began to dry friction; in addition, most of the seal in the open, also briefly dry friction or rubbing occurs in semi stopping. Because of the sealing surface friction coefficient increases dry friction and wear will increase, resulting in seal ring burning or thermal stress cracking, thus leak. To do this, the seal material requires a high temperature and good tribological properties.

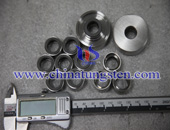

Silicon carbide seal material has its own unique tribological properties, such as good thermal conductivity, self-lubricating, high hardness, it is possible to meet the requirements of various industries seal. Silicon carbide seal material self-lubricating is mainly due to silicon carbide, graphite or carbon particles contains small amount of, at the time of rotation of the sealing surface, these small particles will quickly graphite layer formed on the end surface of the graphite film, play solid lubricant agent, the silicon carbide sealing material, when the pair of carbon graphite and silicon carbide in each case are very small friction coefficient (0.1 or so), which is mainly lubricating graphite.

When silicon carbide seal material paired with other materials, in order to efficiently reduce the friction coefficient, generally using the sealing liquid, so that the formation of a liquid film between the seal faces, using membrane pressure effect plays the role of lubrication, the main methods being taken: 1. a processing fluid dynamic pressure groove; 2.Preparation of the seal faces has a spherical pore silicon carbide seal ring, spherical micron pore size, porosity generally 4 %to 6%; 3.by laser technology and other means, in the silicon carbide seal. the faces of a certain amount of pores, pore size and pore depth are micron size.