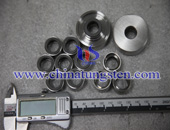

High Speed Silicon Carbide Mechanical Seal

High speed silicon carbide mechanical seal small proportion of small centrifugal force as the ring generated at high speeds, vibration and deflection is reduced, so that the pressure seal faces is relatively stable, relatively fixed friction trajectory. In addition, the thermal properties of high speed with excellent silicon carbide mechanical seals to avoid generating heat Couture lines, and thermal deformation is small, it is possible to ensure a good fit seal face.

SiC material because of its excellent mechanical properties, corrosion resistance and good tribological properties, as a high speed silicon carbide mechanical seal material gradually developed in a number of areas and applications. In the high-speed operation, due to the high speed line, heat and vibration friction wear paid work will be an important issue to be faced in the process, therefore, requires a rotating seal the material should have high strength and low density. Such small rotary ring running at high speed centrifugal force generated, due to vibration and deflection is small, thereby maintaining a constant seal face bonded.

High speed silicon carbide mechanical seals has much smaller density than the carbide material, and has a high modulus of elasticity, to ensure that the silicon carbide seal face difficult conditions in the high-speed deformation and vibration, maintain end face stable fit. Due to the low density of silicon carbide, good thermal performance, low friction coefficient, has obvious advantages in high-speed rotary sealing material, it is widely applied to the mechanical seal ring hard.