Silicon Carbide Seals Superiority

Sealing means from the current industrial use of view, the presence of most poor sealing performance, easy corrosion, defects such as short working life. The reason is because these devices are mostly seals made of metal material, when used in fluid sealing, the fluid medium chemical seals will perform erosion, resulting in the functional decline, it can be disabled , while the mechanical seal leakage, 80% to 95% is caused due to the seal face, to this end, the mechanical seal is essential to pay selected material.

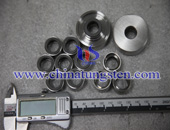

Most mechanical seal ring of hard material is generally used in hard alloy, stainless steel, titanium, ceramics, etc., a metal material due to poor corrosion resistance, corrosion often can not apply in the case of high-speed high-pressure applications, a ceramic material, e.g. Al2O3, ZrO2, SiC, etc., are mostly ionic bond and a covalent bond strong material, which, compared with the metals and polymers having high melting point, good corrosion resistance and oxidation resistance, and high-temperature hardness and high strength, particularly carbonized silicone carbide seals can overcome many of the deficiencies in the sealing industry increasingly popular.

Most mechanical seal ring of hard material is generally used in hard alloy, stainless steel, titanium, ceramics, etc., a metal material due to poor corrosion resistance, corrosion often can not apply in the case of high-speed high-pressure applications, a ceramic material, e.g. Al2O3, ZrO2, SiC, etc., are mostly ionic bond and a covalent bond strong material, which, compared with the metals and polymers having high melting point, good corrosion resistance and oxidation resistance, and high-temperature hardness and high strength, particularly carbonized silicone carbide seals can overcome many of the deficiencies in the sealing industry increasingly popular.